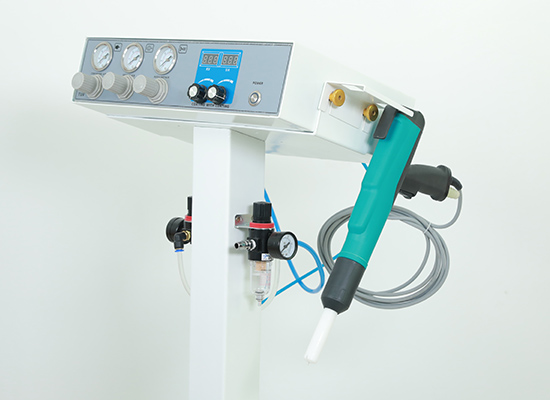

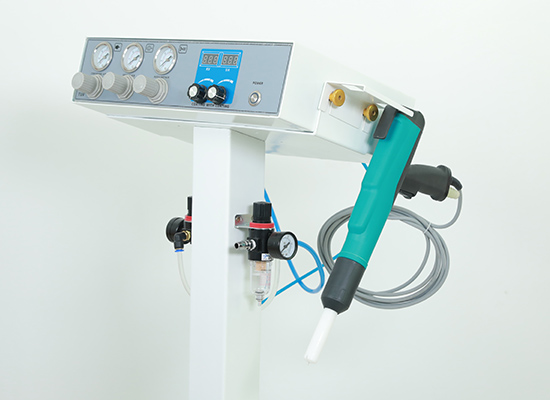

1. Electrostatic Spray Equipment Overview and Components

Electrostatic Spray Equipment Factories specialize in devices that use charged particles to evenly coat surfaces. Key components include a high-voltage generator, spray gun, fluid reservoir, and grounding system. The equipment often features adjustable voltage settings and corrosion-resistant materials like aluminum or stainless steel for durability in industrial environments.

2. Electrostatic Spray Equipment Applications

This technology is widely used in automotive painting, aerospace coating, medical device sterilization, and agricultural disinfection. Electrostatic spray equipment ensures efficient material use by attracting particles to surfaces, reducing waste, and improving coverage on complex shapes.

3. Electrostatic Spray Equipment Pricing

Prices range from 1,000forportablehandheldunitstoover50,000 for large industrial systems. Automated models with advanced controls or custom configurations cost more. Mid-range options (5,000–15,000) suit most commercial needs while balancing performance and budget.

4. How to Use Electrostatic Spray Equipment Properly

Ensure the equipment is grounded to prevent static discharge. Adjust voltage based on material conductivity and target surface. Maintain a consistent distance (6–12 inches) from the surface for uniform coating. Clean the nozzle and reservoir after each use to avoid residue buildup.

5. Tips for Choosing Electrostatic Spray Equipment

Prioritize voltage adjustability for versatility across materials. Check compatibility with solvents or chemicals in your workflow. Opt for lightweight, ergonomic designs if used frequently. Verify certifications (e.g., OSHA compliance) and warranty coverage for long-term reliability.

6. Safety Precautions for Electrostatic Spray Equipment

Operators must wear insulated gloves and goggles to prevent electric shock. Avoid using near flammable materials due to spark risks. Regularly inspect cables and connectors for damage. Ensure proper ventilation to disperse fumes from coatings or disinfectants.

7. Design Advantages of Electrostatic Spray Equipment

Modern designs emphasize energy efficiency, portability, and modularity. Features like automatic shutoff, touchscreen controls, and quick-change nozzles boost productivity. Factories integrating IoT-enabled diagnostics enable real-time performance monitoring and maintenance alerts.

8. Electrostatic Spray Equipment Q&A

Q1: How does electrostatic spray coating improve efficiency?

A: The charged particles adhere better to surfaces, reducing overspray by up to 50% and saving material costs.

Q2: Can electrostatic sprayers apply thick coatings?

A: Yes, but viscosity adjustments or specialized nozzles may be required for optimal results.

Q3: Are electrostatic spray guns safe for indoor use?

A: Yes, provided the area is well-ventilated and operators follow safety protocols.

Q4: What industries benefit most from electrostatic spray equipment?

A: Automotive, healthcare, and manufacturing industries rely on it for precision and waste reduction.

Q5: How to maintain an electrostatic spray system?

A: Clean components after each use, inspect electrical parts monthly, and replace worn nozzles annually.

This guide highlights critical aspects of electrostatic spray equipment, helping businesses optimize operations, ensure safety, and select the best systems for their needs.

Statement: Hangzhou Huaxiang Coating Equipment Co., Ltd Chinese Powder Coating Equipment facturers provide you with customized equipment for various types of Powder Coating Lines, Powder Coating Ovens, Powder Coating Booths,Powder Coating Guns, etc. For inquiries! Contact us at

Email: gezx@cncolourspray.com

WhatsApp: +86 13335812068