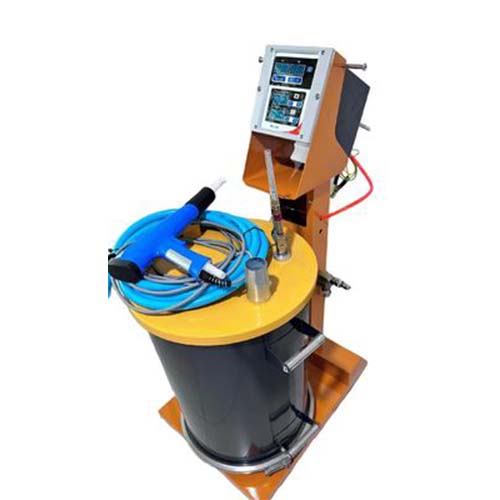

Powder Coating Machine Spare Parts Market Demand and Price Introduction

Powder Coating Machine Spare Parts are the critical elements that ensure the reliability and longevity of any powder coating operation, from a small workshop to a large industrial line. The demand for genuine and high-quality Powder Coating Machine Spare Parts is consistent, driven by the need to minimize costly downtime and maintain finish quality. These parts encompass everything from wearable components like nozzles and electrodes for a Powder Coating Spray Machine to major assemblies like heating elements for an Industrial Powder Coating Oven. The Powder Coating Machine Spare Parts price spectrum is broad, reflecting this variety. Simple consumables may cost a few dollars, while specialized proprietary components or electronic control boards for a Powder Coating Manufacturing Machine can represent investments of hundreds or thousands of dollars. A strategic inventory of Powder Coating Machine Spare Parts is a smart operational practice.

Powder Coating Machine Spare Parts Coating Project Introduction

Powder Coating Machine Spare Parts play a vital role in the success and continuity of every coating project. For a project using a Small Parts Powder Coating Machine, having spare nozzles, fluidized bed membranes, and powder pump seals on hand prevents interruptions when coating batches of brackets or fasteners. In a larger project involving a full Powder Coating Manufacturing Machine line, the proactive replacement of wear items like conveyor chain links, spray booth filter cartridges, and burner nozzles for the Industrial Powder Coating Oven is part of standard preventive maintenance. Whether it's a DIY enthusiast needing a new high-voltage cable for their gun or a factory replacing a programmable logic controller, the right Powder Coating Machine Spare Parts ensure that projects finish on time and to specification.

Powder Coating Machine Spare Parts Surface Treatment Process Technical Characteristics

Powder Coating Machine Spare Parts are engineered with specific technical characteristics to match their function within the coating process. A replacement electrostatic spray gun nozzle, for instance, is precisely machined to create the correct powder cloud pattern and maintain consistent electrostatic charge transfer. Wear parts for a Powder Coating Sieving Machine, such as the mesh screens, are defined by their exact micron rating to ensure proper powder filtration. Heating elements for an Electric Powder Coat Oven are designed to provide uniform heat distribution and rapid thermal response to maintain the exact Oven Temperature For Powder Coating. Using Powder Coating Machine Spare Parts that meet the original equipment manufacturer's technical specifications is non-negotiable for preserving the designed efficiency, transfer rates, and finish quality of the entire system.

Powder Coating Machine Spare Parts Installation Tips

Installing Powder Coating Machine Spare Parts correctly is fundamental for safety and performance. Always disconnect the machine from all power and air supplies before beginning any replacement. Refer to the equipment's service manual for specific procedures and torque specifications. For electrical components, ensure proper grounding and connection integrity. When replacing wear parts in the powder path—like a pump insert or gun nozzle—conduct a thorough cleaning of the surrounding area first to prevent contamination of the new part. After installing major Powder Coating Machine Spare Parts, such as a new control board for a Powder Coating Paint Machine, perform a controlled test run without powder to verify basic functions. For complex installations, especially on safety-critical systems like oven burners, engaging a qualified technician from your Powder Coating Machine Suppliers is highly recommended.

Powder Coating Machine Spare Parts Manufacturing and Production Cost

The manufacturing of high-quality Powder Coating Machine Spare Parts involves precision engineering and material science. Production costs are influenced by the complexity of the part, the materials used (e.g., specialized plastics, stainless steel, high-grade ceramics for insulation), and the required tolerances. A simple spacer may be inexpensive to produce, while a high-voltage generator for an electrostatic gun requires sophisticated electronics and safety testing. For end-users, the cost of Powder Coating Machine Spare Partsmust be evaluated against the cost of production downtime. While generic or copied parts may have a lower purchase price, they often carry a higher total cost due to potential machine damage, inconsistent performance, and more frequent failure. Investing in genuine or OEM-equivalent Powder Coating Machine Spare Partsfrom reputable sources protects your larger equipment investment.

Powder Coating Machine Spare Parts Equipment Q&A

How to Identify the Correct Powder Coating Machine Spare Parts for Your Equipment?

Identifying the correct Powder Coating Machine Spare Parts requires accurate machine information. Start by locating the equipment nameplate and model number, which is often found on the main control unit, spray gun handle, or oven chassis. Consult the original operation and parts manual, which should contain a illustrated parts breakdown with reference numbers. If the manual is lost, contact the equipment manufacturer or your original Powder Coating Machine Suppliersdirectly with the model and serial numbers. For visual parts like nozzles or filters, clear photographs with a scale (like a ruler) can also help suppliers identify them. Using incorrect Powder Coating Machine Spare Parts can lead to poor performance or equipment damage, so taking time for accurate identification is essential.

How to Source Reliable Powder Coating Machine Spare Parts Suppliers?

Sourcing reliable Powder Coating Machine Spare Parts involves finding suppliers with expertise and a proven track record. The first point of contact should always be the original equipment manufacturer (OEM) or the Professional Powder Coating Machine Manufacturers who supplied your line. They guarantee part compatibility and often provide warranty coverage. For older equipment or to explore options, specialized industrial parts distributors and reputable online platforms that focus on coating equipment are alternatives. Key factors to evaluate include the supplier's technical knowledge, availability of detailed product information, clear return policies for incorrect parts, and reasonable shipping times. Reading customer reviews and asking for recommendations from industry peers can also guide you to trustworthy Powder Coating Machine Spare Parts suppliers.

How to Maintain an Inventory of Critical Powder Coating Machine Spare Parts?

Maintaining a smart inventory of critical Powder Coating Machine Spare Parts balances cost with operational risk. Start by listing all high-wear consumables specific to your machines, such as nozzle sets for your Powder Coating Spray Machine, filter socks for the recovery system, and specific gaskets. Review the equipment maintenance manuals for recommended spare parts lists. Analyze your production history: which parts have failed before and caused the longest downtime? These are your top-priority Powder Coating Machine Spare Parts to stock. For very expensive or rarely failing components, consider a "just-in-time" agreement with your supplier rather than holding stock. Keep your inventory log updated, store parts in a clean, dry environment, and periodically check expiration dates on items like seal kits.

How to Troubleshoot Issues Caused by Worn Powder Coating Machine Spare Parts?

Troubleshooting issues often leads back to worn Powder Coating Machine Spare Parts. Common symptoms include poor powder adhesion (check gun electrode and ground connections), uneven spray pattern (inspect nozzle for wear or clogging), low powder output (examine pump seals and fluidizing membrane), or inconsistent oven temperature (verify heating elements and sensors). A systematic approach is key. Isolate the problem to a specific machine section, then inspect the wearable components in that area. Compare the performance of a Small Powder Coating Machinebefore and after a known-good part is swapped in as a test. Keeping a log of part replacement intervals helps predict failures before they cause a defect in a Powder Coating Paint Machineproject.

How to Evaluate the Quality of Third-Party Powder Coating Machine Spare Parts?

Evaluating third-party Powder Coating Machine Spare Parts requires diligence to ensure they match OEM quality. Request material certifications for critical components, especially those in contact with powder or handling high voltage. Inspect the machining quality and finish—parts should be free of burrs and flash. Compare dimensions and tolerances with the original part if possible. For electrical components, verify safety certifications. Research the manufacturer of the spare part; established brands in the coating industry are generally reliable. Test a small quantity first in a non-critical application to assess performance and longevity. While third-party Powder Coating Machine Spare Parts can offer cost savings, the priority must always be on safety, compatibility, and maintaining the quality output of your coating line.

Statement: Hangzhou Huaxiang Coating Equipment Co., Ltd Chinese Powder Coating Equipment facturers provide you with customized equipment for various types of Powder Coating Lines, Powder Coating Ovens, Powder Coating Booths,Powder Coating Guns, etc. For inquiries! Contact us at

Email: gezx@cncolourspray.com

WhatsApp: +86 13335812068