Powder Spraying Oven Supplier Market Demand and Pricing

The demand for Powder Spraying Oven Supplier services has grown significantly across industries like automotive, aerospace, and furniture. These ovens ensure durable, eco-friendly finishes while reducing VOC emissions. Prices vary based on capacity (small batch ovens start at $5,000, industrial-scale units exceed $50,000). Factors like energy efficiency and customization affect costs.

Powder Spraying Oven Supplier Coating Project Overview

Powder Spraying Oven Suppliers provide equipment for curing powder-coated surfaces. Projects typically involve pre-treatment, spraying, and curing stages. These ovens integrate with automated lines for high-volume production or standalone setups for smaller operations.

Powder Spraying Oven Supplier Surface Treatment Technology

The process uses electrostatic application of dry powder, cured in ovens at 150–200°C. This creates a chemically resistant layer. Advanced Powder Spraying Oven Suppliers offer infrared or convection heating for uniform results.

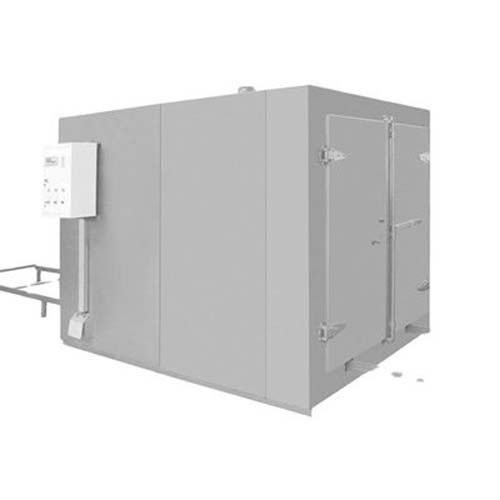

What Is a Powder Spraying Oven Supplier?

A Powder Spraying Oven Supplier manufactures ovens that cure powder coatings. These units feature precise temperature control, airflow systems, and safety mechanisms to handle flammable powders.

Components of Powder Spraying Oven Supplier Systems

Heating Chamber: Insulated space with heating elements.

Convection System: Ensures even heat distribution.

Control Panel: Digital interfaces for temperature and timing adjustments.

Advantages of Powder Spraying Oven Suppliers

Eco-Friendly: No solvent emissions.

Cost-Effective: High material utilization (95%+).

Durability: Resistant to chipping and corrosion.

Powder Spraying Oven Supplier Q&A

How to Choose a Powder Spraying Oven Supplier?

Prioritize suppliers with Energy-Efficient Designs and ISO certification.

How to Maintain Powder Spraying Ovens?

Regular filter cleaning prevents Powder Contamination.

How to Optimize Curing Time?

Adjust settings based on Material Thickness.

How to Ensure Safety?

Install Explosion-Proof Ventilation for flammable powders.

How to Reduce Operational Costs?

Use Recirculating Air Systems to cut energy use.

Statement: Hangzhou Huaxiang Coating Equipment Co., Ltd Chinese Powder Coating Equipment facturers provide you with customized equipment for various types of Powder Coating Lines, Powder Coating Ovens, Powder Coating Booths,Powder Coating Guns, etc. For inquiries! Contact us at

Email: gezx@cncolourspray.com

WhatsApp: +86 13335812068