Oven Powder Coating Spray: Your Guide to Quality Coating Solutions

Oven Powder Coating Spray systems meet demands across industries like automotive, furniture, and manufacturing. Prices range: small hobbyist setups start around (1,000, mid - size commercial units hit )5,000 - (15,000, and large industrial systems go over )50,000 based on capacity and features.

Oven Powder Coating Spray: Introduction to Coating Projects

Oven Powder Coating Spray is key in various projects. Auto shops use it for rims, engine parts, and chassis, giving durable finishes against road elements. Furniture makers coat metal chairs, tables, and frames, making them rust - resistant for indoor and outdoor use. Metal fabricators apply it to gates, railings, and toolboxes, enhancing longevity and appearance.

Oven Powder Coating Spray: Surface Treatment Process Technology

Oven Powder Coating Spray process starts with cleaning the surface. Degreasing removes oils, and sandblasting or chemical etching creates a rough texture for better adhesion. The spray gun applies electrostatically charged powder, which sticks to the grounded surface. Then, the item goes into the oven, heated to 350 - 450°F (175 - 230°C), melting the powder to form a smooth, cured layer.

Oven Powder Coating Spray: What Is It?

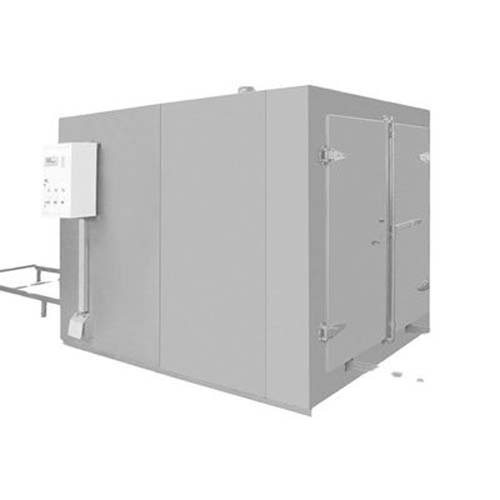

Oven Powder Coating Spray refers to equipment and methods for applying powder coatings cured in an oven. The spray system includes a gun, powder feeder, and compressor. The oven is a heated chamber. Together, they apply a dry powder that melts and hardens, forming a tough coating without liquid solvents.

Oven Powder Coating Spray: Components and Their Roles

Spray Gun: Delivers powder, using electrostatic charge to attract powder to the surface. Has adjustable settings for powder flow and spray pattern, ensuring even coverage.

Powder Feeder: Holds and feeds powder to the gun. Uses air pressure to move powder, with a hopper to store it. Prevents clumping for consistent flow.

Curing Oven: Heats coated items to cure the powder. Has temperature controls to maintain precise heat levels. Insulated walls keep heat in, and fans circulate air for uniform curing.

Oven Powder Coating Spray: Advantages

Oven Powder Coating Spray offers strong, long - lasting finishes that resist chips, scratches, and UV damage. It’s eco - friendly, with no harmful VOCs. Powder can be recycled, reducing waste. It provides a wide range of colors and textures, from matte to glossy. The process is efficient, with quick curing times and minimal drying needed.

Oven Powder Coating Spray: FAQ

How to Select the Right Oven Powder Coating Spray for Home Use?

For home use, consider the size of items. A small oven (24x24x24 inches) and a handheld spray gun work for small parts. Look for easy - to - use controls, like adjustable temperature in the oven and powder flow in the gun. Check if it’s portable and has safety features like overheat protection. A 110V system is better for home electrical setups.

How to Ensure Safety When Using Oven Powder Coating Spray?

Wear protective gear: gloves, goggles, and a respirator to avoid inhaling powder. Keep the workspace ventilated to prevent powder buildup. Never spray near open flames as some powders are flammable. Follow oven safety: don’t leave it unattended, and keep flammables away. Disconnect power when cleaning or maintaining equipment.

How to Clean Oven Powder Coating Spray Equipment Properly?

After use, disassemble the spray gun. Soak parts in warm, soapy water to remove powder residue, then rinse and dry. Clean the powder feeder’s hopper with a brush to avoid cross - contamination of colors. Wipe the oven interior with a dry cloth to remove excess powder. Vacuum the workspace to clean up loose powder.

How to Fix Uneven Coating with Oven Powder Coating Spray?

Check the spray gun: adjust the powder flow and spray pattern. Hold the gun 6 - 10 inches from the surface, moving steadily. Ensure the surface is clean; re - clean if needed. In the oven, make sure items are spaced for even heat. If the oven has hot spots, rotate items during curing.

How to Choose Oven Powder Coating Spray for High - Volume Production?

Opt for a large oven with conveyor systems to handle continuous loading. A high - capacity powder feeder reduces refills. Look for a spray gun with automatic operation for consistent results. Choose an oven with quick heat - up and recovery times. Ensure the system integrates with other production line equipment for efficiency.

Statement: Hangzhou Huaxiang Coating Equipment Co., Ltd Chinese Powder Coating Equipment facturers provide you with customized equipment for various types of Powder Coating Lines, Powder Coating Ovens, Powder Coating Booths,Powder Coating Guns, etc. For inquiries! Contact us at

Email: gezx@cncolourspray.com

WhatsApp: +86 13335812068